Phone: 8613421351153

Comparison of CNAS and UL composite floor slabs reports

Some projects require composite floor slabs to be UL certified and achieve two-hour fire resistance. Solideck has conducted a two-hour fire resistance test at the CNAS laboratory in China and passed the test, achieving two-hour fire resistance. Now let’s analyze the similarities and differences between the CNAS certified composite floor fire resistance test report and the UL fire resistance certification.

Similarity

Whether it is CNAS fire resistance test or UL certification, both are feasible guarantees for the fire resistance performance of steel deck composite floor. From the test results to the test principles, they are similar in nature.

The core objectives are the same

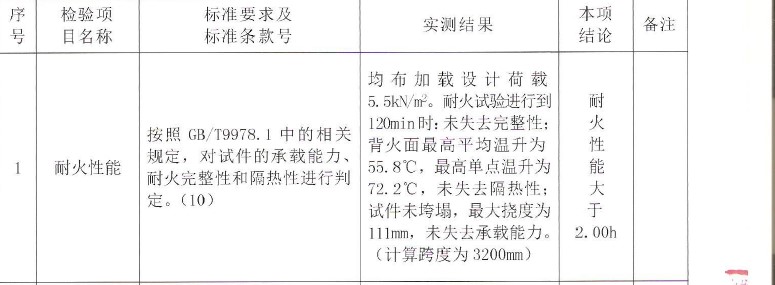

They all aim to evaluate the load-bearing capacity, thermal insulation and integrity (resistance to flame penetration) of the floor slab under standard fire conditions to ensure the stability of the structure during a fire.

Similar test principles

Both use standard time-temperature curves (such as ISO 834 or ASTM E119) to simulate the temperature rise environment of a fire.

Measurement indicators include:

Load-bearing capacity (whether it collapses)

- Thermal insulation (temperature rise on the back of the fire surface ≤ 140℃)

- Integrity (whether there are penetrating cracks/flames).

- Solideck’s fire resistance test in CNAS laboratory is also carried out according to the above test principles.

There is a correspondence between the systems

The fire resistance rating of China CNAS Laboratory (such as 2 hours) and the rating of UL (such as 2hr ) are comparable.

Differences

Since the two systems are derived from different standards, there are still some differences in the reports.

Test Standards

The testing standard of CNAS laboratory is China’s GB/T 9978. The standard of UL certification is UL 263 / ASTM E119.

Test furnace direction

The test furnace required in the CNAS laboratory is a horizontal furnace that simulates the scenario of a normal floor fire and more closely resembles the scenario of a fire on an actual floor slab.

UL certification requires only vertical furnaces, and the floor slab needs to simulate the installation of vertical partition components.

From the perspective of testing methods, it seems that the CNAS experimental test is more in line with reality.

Load application method

The CNAS laboratory test load application method is mainly uniformly distributed load, simulating the actual use load.

The UL certification test load application method allows concentrated loads and pays more attention to local load-bearing, May affect deformation and failure modes.

Integrity determination

The integrity assessment of the CNAS laboratory is achieved through a combination of cotton pad ignition test and gap probe detection.The integrity determination of UL certification focuses on gap probe detection, and cotton pads are not mandatory.

In terms of integrity determination, CNAS laboratory may be more strict.

Conclusion

From the above analysis, the fire resistance test report of CANS laboratory is similar to UL certification, whether it is the test purpose, test principle and test method, or the fire resistance test of CANS is more stringent.

For super high-rise projects, and the floor slab load is uniformly distributed with little concentrated load; and considering the fire state of the floor slab in multiple horizontal directions, we believe that the fire resistance test report of the CNAS laboratory can be used in this project to achieve the effect of UL certification.