Phone: 8613421351153

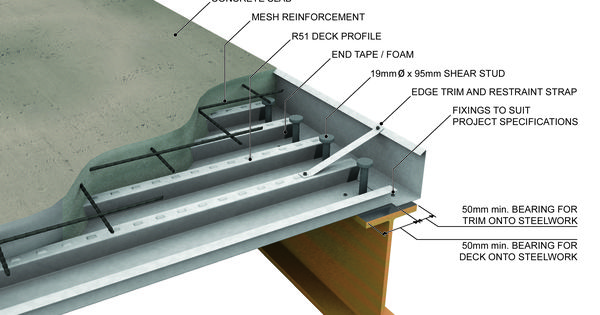

composite steel deck concrete pouring

Whether you have a composite or non-composite floor slab, the pouring of concrete is very important. Not only is the quality of the building involved, but also the safety of the construction phase.

Verification of steel decks prior to pouring

Before the concrete is poured, various inspections are done to check the installation of the composite steel deck, clean the steel deck of debris, and eliminate safety hazards.

Verification of steel deck fixing

Verification of the fixing of the steel deck is the first step in the process, if the fixing is substandard or not fixed, it may result in overturning during the concrete pouring process to the extent of creating a safety incident. In accordance with the drawings, check in the following order: fixing of the steel deck to the steel beams, fixing between the steel decks, fixing of the Pour stop to the steel beams, fixing of the pegs to the steel beams. Ensure that the above fixings are qualified, if not, reinforcement measures need to be taken.

Checking the laying of reinforcing steel

Check the arrangement of reinforcement at the slab surface and at the bottom of the slab (non-conforming slab), measure the thickness of the protective layer and ensure the distance between the reinforcement and the surface and bottom of the slab, and check the fixing of the end reinforcement to the composite steel deck.

Clearing debris from steel decks

Before pouring concrete, the steel deck must be cleared of debris and dust, grease and so on. These debris will make the concrete and steel deck interaction is impeded, but also make the floor of the existence of certain hidden problems, so that the floor of the floor when subjected to a certain load, weakening the composite effect of concrete and steel deck.

Inspection of security measures

Check safety features before concrete is poured. In steel deck areas where personnel and trolleys are walking areas, scaffolding should be laid to facilitate walking while reducing the forces on the steel deck. If temporary supports are provided on the steel deck, check that they are securely fastened and take into account any deflections that may occur during concrete placement.

Pouring of concrete

The concrete was poured in sequence. It is advisable to pour concrete in the part directly facing the steel beam or temporary support, and the scope of pouring or the temporary accumulation caused by pouring concrete shall not exceed 1/6 slab span of the steel beam or temporary support, and shall be quickly spread out in all directions to avoid over-expansion of the accumulation.Dumping of concrete in the mid-span (temporary support as bearing) area of the floor joist is strictly prohibited. If pumped concrete is used, its pipe supports should be supported on steel beams.

No other loads shall be placed on the floor surface until the concrete has reached 75% of its design strength.

The pouring of concrete is the last cloth to complete the non-composite floor slab or composite floor slab, after all the previous steps are perfectly completed, must pay attention to the pouring of coagulation to ensure the quality and safety of the floor slab in the use stage.