Phone: 8613421351153

Connection of steel decks

Solideck has written two articles on the connection of steel decks, which will be summarized into a systematic text today in the form of three or an articles. Builders or designers can use this as a reference.

Connection forms for steel decks

There are a variety of ways to connect steel decks, and the choice of the specific implementation can be made based on the type of steel deck being used and the specific requirements of the project. Some common connection methods include.

Welding

Welding is a common method of joining steel decks and involves using heat to fuse two pieces of metal. It is a fast and effective method, but requires a skilled welder to operate, but can be expensive.

Shear Connectors

Shear connectors are used to connect composite steel decking to concrete. These connectors are welded to the top flange of the steel beams to provide a strong connection between the steel deck and the concrete slab.

Screw Attachment

Screw attachment is accomplished by drilling holes in the deck and using screws to secure it to the support structure. This method is suitable for lighter decks, such as steel roof decks, and can be easily adjusted as needed.

Connecting steel decks to different objects

The specific ways of connecting steel decks to different objects vary. Mainly divided into several types: steel deck and steel beam connection, steel deck and concrete connection, steel deck itself connection, etc..

Connection of steel decks to steel beams

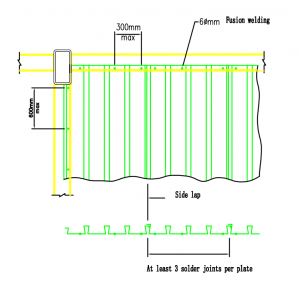

Steel deck to steel beam connections are what most projects encounter. Steel deck to steel beam connections are mostly welded, but will also be shear member methods. The welding method is usually fusion welding, the diameter of the fusion welding should be not less than 6mm, the distance is not less than 300mm. fusion welding connection first to ensure that the steel deck and steel beams are fixed together, and then you can lay a good steel deck as a platform for operation. In order to increase the shear capacity of the combined floor slabs, shear members (pins) are usually welded to the steel beams through the steel deck, and the selection of shear members is based on the structural engineer’s calculations.

Connection of steel deck to concrete beams

Solideck may have to dedicate an article to the connection and fixing of steel decks to concrete beams, this article will only provide a brief overview. Regarding the connection and fixation of the steel deck and the concrete beam, it is generally accomplished by setting up the embedded parts on the concrete beam, and then the steel deck is connected and fixed with the embedded parts, and the specific form of operation refers to the program of connecting the steel deck and the steel beam.

Steel deck to steel deck connection

Regarding the steel deck to steel deck connection is the lateral connection of two steel decks. There are two ways of connecting steel decks to each other for reference: steel decks form interlocking lateral lap joints through male and female edges; and self-tapping screws or rivets are used to connect them. Using interlocking lateral lap connection, there should be effective mechanical fixing, such as calipers, generally SD51-915, SD76-915 and other board types are used; while using self-tapping screws or rivets to connect, the fixing distance is less than 500mm, generally SD46-600, SD65-555 and other steel decks are used.

The above is the steel deck connection form and different objects connection method, in the later articles will also be in the form of graphic specific implementation practices.