Phone: 8613421351153

What should be paid attention to in the construction of corrugated galvanized sheets? Here are five aspects:

(1) The size of the steel components should be checked first during the lofting operation to avoid lofting errors caused by the installation errors of the steel components.

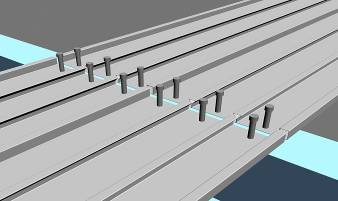

(2) The edges, holes, and corners of the column should be cut out, and the installation speed can be accelerated and the installation quality can be ensured by doing it on the ground.

(3) When laying the corrugated galvanized sheets, fix it first. The method is to fix the end and the flange of the steel beam by spot welding with a distance of 200 mm, or each rib of the steel plate, when the profile steel sheeting is longitudinally connected to the beam, fixed by jump welding, with a distance of 450 mm ~600 mm, the overlap of two adjacent steel form deck is also fixed by pick welding. When laying, the corrugated galvanized sheets female buckle is used as the reference starting edge, and the laying is carried out in sequence according to the principle of first inside and then outside (the main radiating road will be paved first).

(4) When installing the steel form deck, the reference line shall be set at both ends of the steel form deck and the flange edge of the span steel beam shall not be less than 50mm.

(5) Visual inspection of studs. Qualified studs should also be hit with a hammer according to the specification to bend them 30°, and check the welded parts for cracks.