Phone: 8613421351153

Application of SD38-914 steel decking in warehouse mezzanine

As people’s material needs continue to grow, the high-frequency turnover of products demands increasingly efficient warehouse operations. Within the same space, achieving higher utilization rates makes warehouse mezzanines a transformative investment. However, the success of any mezzanine project hinges on one critical component—steel decking. Among numerous options, the SD38-914 steel decking has emerged as the preferred choice, delivering unmatched strength, efficiency, and versatility for modern industrial applications.

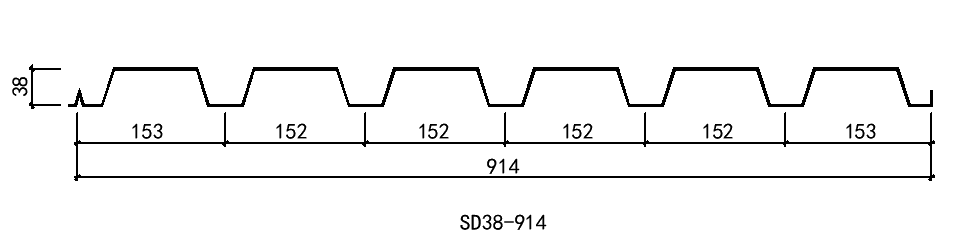

Profile of SD38-914

SD38-914 is an example of a low-ribbed steel floor deck, often used for thin floors and flexible roofs. It is 1.5 inches high, has 6 ribs, and is 3 feet (914) wide.We can provide raw materials with thickness of 18-24 gauge, and galvanized sheet of 120 g/m2–275 g/m2,or color-coated sheet available.

SD38-914 finds extensive application not only in steel roofing but also in flexible roofing systems. Its most common use is in thin floor slabs, particularly in warehouse mezzanines.

Advantages of SD38-914

The advantages of SD38-914 for warehouse mezzanines are determined by the inherent characteristics of the steel floor deck itself.

Thickness of SD38-914 Composite Floor Slab

SD38-914 The 1.5-inch height allows for thinner composite floor slab when combined with concrete. Using 2-inch or 3-inch deck heights would increase composite floor slab thickness and reduce the usable height of the warehouse. Deck heights below 1.5 inches would result in insufficient stiffness, thereby reducing the composite slab’s rigidity and strength and compromising the slab’s performance.

SD38-914 steel decking type advantages

The SD38-914 has a rib spacing of 6 inches (152 mm). This smaller spacing ensures the steel decking’s rigidity, providing the composite floor slab with a certain level of comfort and low vibration during use. Furthermore, its corrugated profile on the sides enhances interaction with the concrete, making the composite floor slab robust.

A Versatile Foundation for Finishes

The SD38-914 floor system provides a robust concrete surface offering incredible versatility for the final floor finish. It can be left as a raw sealed concrete surface for purely utilitarian purposes. Alternatively, it can be coated with epoxy for easy cleaning and chemical resistance, fitted with raised flooring for cabling, or covered with vinyl tiles or carpet in office or showroom spaces. This flexibility allows a single mezzanine to serve multiple functions within a warehouse.

Design of the SD38-914 Floor Slab System

The design of SD38-914 in the warehouse mezzanine includes the following items:

Composite Floor Slab Design

The most fundamental design approach for SD38-914 floor decking involves forming a composite slab with concrete. During the design process, the steel decking is not calculated as temporary form work but rather as tensile reinforcement at the bottom of the concrete slab.

Working Principle: After concrete is poured and cured, the protrusions on the steel decking surface interlock with the concrete, bonding the two materials together. Under load, the steel decking resists tensile forces while the concrete resists compressive forces. This composite action enables the entire system to withstand significantly greater loads than non-composite systems of equivalent weight.

Floor Slab Load Analysis and Bearing Capacity Calculation

Intermediate floor slabs are typically new additions. Design considerations must account not only for the complex load combinations acting on the slab itself, but also for compatibility with the existing structure. All loads must be carefully evaluated during design:

- Dead Load (DL): Refers to the static weight of the system itself, including steel decking, concrete fill, and any permanent finishes such as epoxy flooring.

- Live Load (LL): Refers to dynamic loads generated during use. For warehouses, live loads can be very high, ranging from 125 lbs/sq ft (approx. 1.7 m²) for bulk storage to 250 lbs/sq ft (approx. 1.7 m²) or higher for forklift traffic and pallet racking.

Deflection and Vibration Control of Floor Slab

- Strength: Not only about preventing collapse, but also about serviceability. If the floor’s strength is insufficient, additional cargo can not be placed on it. When selecting SD38-914, a yield strength of 50 ksi (350 MPa) is typically chosen, enabling the SD38-914 floor slab system to provide enhanced load-bearing capacity.

- Stiffness: The profile depth provides high rigidity, limiting deflection under load. Building codes typically restrict live load deflection to L/360 (where L is the span). The SD38-914 design meets or exceeds this standard, ensuring the floor’s sturdiness and durability. Additionally, it guarantees low vibration levels, ensuring functional comfort.

Material Specifications and Corrosion Protection

SD38-914 steel decking are typically constructed from high-strength cold-rolled steel. The steel grade or thickness is a primary variable in the design. Ga 20 deck may be suitable for lighter loads, while heavy-duty applications may require a 16-gauge deck. As mentioned earlier, SD38-914 generally employs a yield strength of 50 ksi. Additionally, deck plates almost always feature a galvanized coating (G60 or G90). This galvanized coating is a critical design feature, providing long-term corrosion resistance in the potentially humid and variable environments of warehouses.

Conclusion

SD38-914 steel decking provides an exceptional foundation for these critical elevated spaces through its proven strength, robustness, durability, and versatility. Designers must leverage its composite action, floor load distribution, and material science principles to create safe, durable, and high-performance elevated floors.