Phone: 8613421351153

Composite steel decking is a versatile and cost-effective building material that is used in many construction projects.To manufacture composite steel decking, thin strips of galvanized steel are cold rolled into corrugated, or ribbed, shapes known as profiles.

Introduction of composite steel decking

The two most common composite steel decking are shallow (dovetail or re-entrant) which are up to 108 mm deep and used for short spans, and deep deck (trapezoidal) which are up to 130 mm deep and used for longer spans.

Each steel decking profile can be manufactured in a different steel gauge according to construction project requirements, usually between 0.75 mm and 1.52 mm. Sheet metal gauges are based on a weight of 20 kg per square inch of thickness.The shape and gauge of the metal deck profile influences factors such as the load capacity, thickness and fire performance of the finished composite floor slab.

The production of composite steel decking

Steel decking profiles are produced by placing the galvanized steel coil on a clamp, placing one side of the galvanized steel coil in a platen press, entering the length of the piece of steel decking, and starting the machine. When the length of the steel decking is reached, the press stops, the cutter cuts the steel decking vertically and a sheet of compliant steel decking is produced.

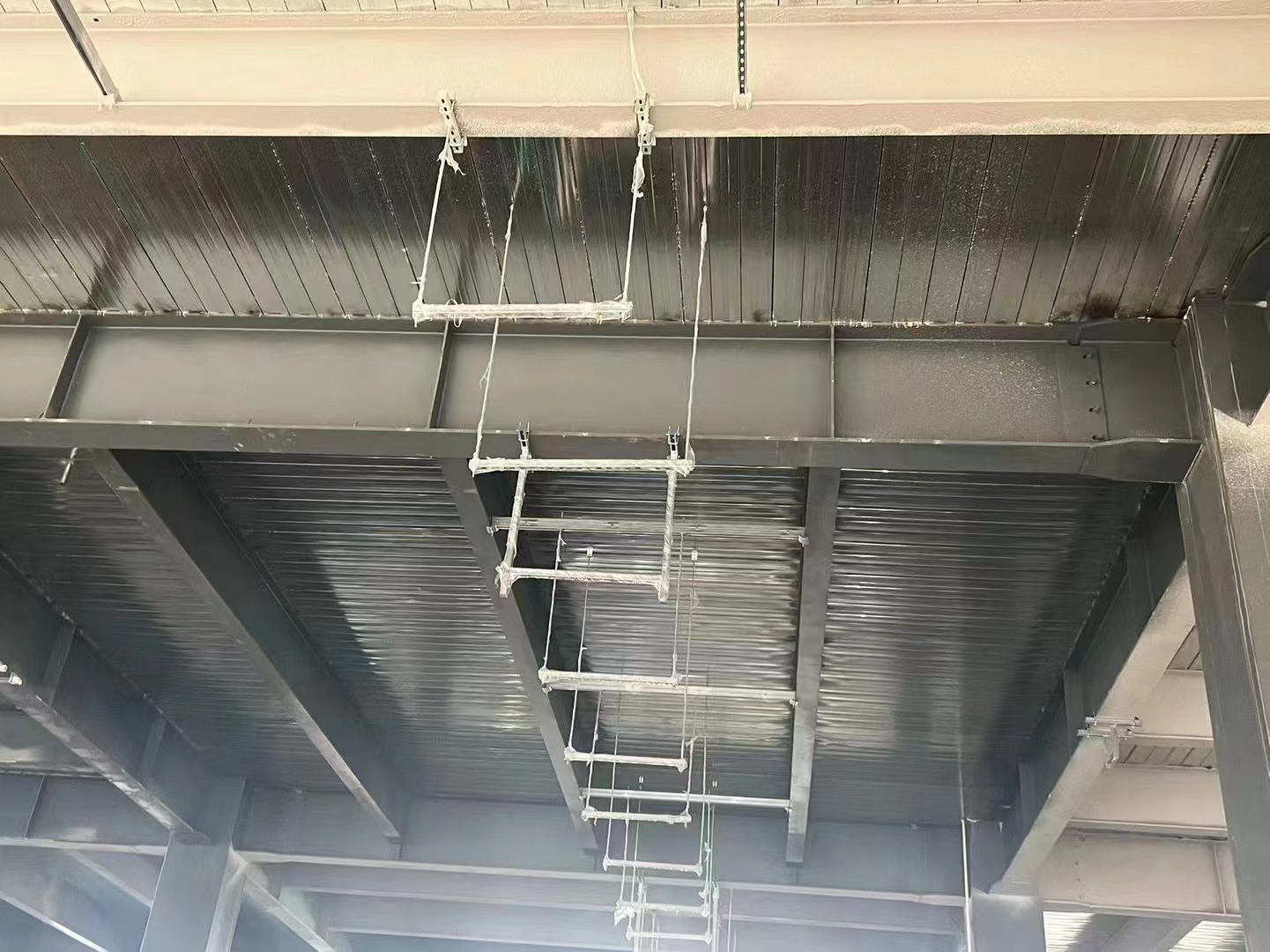

Formation of Composite Floors

Once the steel deck is machined, it can be mounted to joists or beams and secured by welding. The next step is to pour concrete on the steel deck. Before pouring the concrete, the pour stop and steel bars have been laid in place. After 24 hours of pouring the concrete, the concrete has formed its initial strength, and the composite floors has basically been made. This can be done with steel ,The decking composite floor slab performs other operations for the platform.