Phone: 8613421351153

Several methods of steel roofing system

With more and more steel structure buildings, steel roofing system is getting more and more attention. No matter what kind of building, steel roofing will face the problems of wind load, snow load, waterproof, corrosion resistance, as well as sound insulation, heat insulation are all problems that need to be considered by designers, and these problems are related to the selection of steel roofing system. In general, there are three types of work methods for steel roofing system.

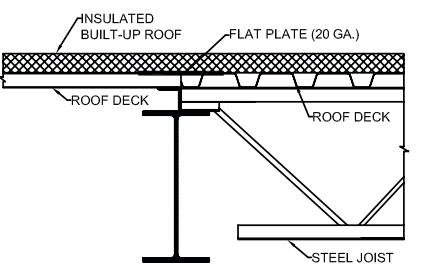

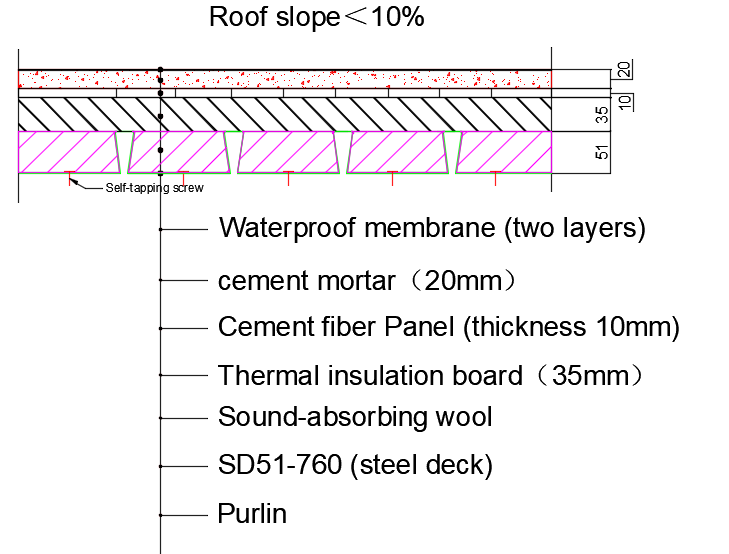

steel roof deck system

In North America, this steel roofing system is used in large numbers and has resulted in a wide range of roof panel types, as seen in SDI’s manufacturer’s product list. This type of roofing system is a roofing system that does not require concrete to be poured over the steel roof deck, and will basically be made up of insulation, waterproofing, and soundproofing. In China, this practice is called “Flexible Roofing“, and I have written an article about it in my blog–The application of steel roof decks in flexible roofs, which can be seen in the picture below. This is a common practice in North America, but there are not many flexible roofing practices in Asia and Australia.

This type of roofing system requires high roof heights and large spans, such as airports, stadiums, theaters, etc. I have seen this type of roofing system at the Los Angeles Airport.

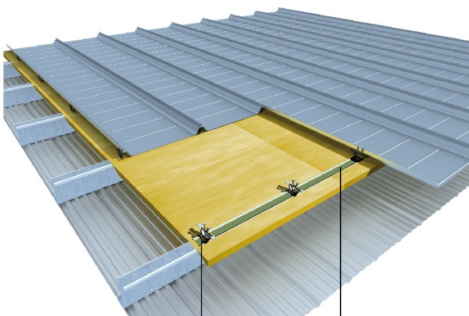

Steel roof panels system

I think that in North America, a steel roof deck is different from a steel roof panel. steel roof panels basically don’t require a waterproofing layer, the system consists of a strong frame-like structure covered with metal sheets, which are either fastened together using panels, overlap joints, or isolated clips. The system consists of a strong frame-like structure covered with metal sheets, which are either fastened together using panels, overlap joints, or isolated clips. The specific practice is to set up an inner liner plate on the lower part of the steel purlin, and on top of the inner liner plate, lay insulation foam, and then install a layer of outer roof panel on the upper part of the insulated surface, such as standing seam roofing or CLIP roofing. standing seam roofing or Clip concealed roofing , see below: Of course, there is also this single-layer steel roof deck, which generally does not have high requirements and is just a simple facility to protect it from wind and rain, such as carports, temporary shelters, etc.

This type of roofing system is used in industrial plants, and commercial facilities more often. Especially for waterproofing requirements are high.

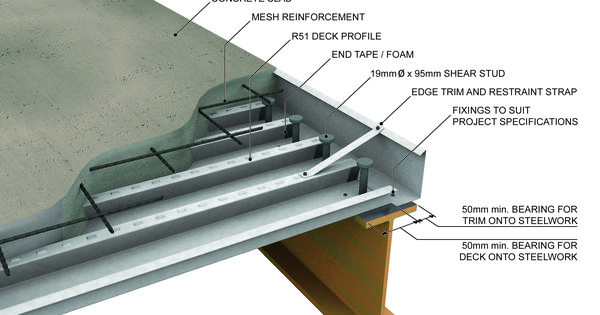

Steel deck composite roofing

Steel deck composite roofing is very common in Asia and Australia, and is not much different from a steel deck composite floor, except that the thickness of the floor slab will be thicker. These steel decks can be either composite metal decking or form decking, and then a certain amount of steel reinforcement is configured according to the load, and concrete is poured on top. Especially in some high-rise buildings or ultra-high-rise buildings, most of the roofs use this form of roof decking. Solideck has done a lot of ultra-high-rise buildings in China and Asia, the roofs are used in this way, and even some airports also use this form of roofing. This is just like a normal concrete roof, which requires a waterproofing layer on top, and then it can be finished once and for all. see below:

According to Solideck’s many years of rich experience, most of these three modes are used, and of course there are roofing sandwich panel systems. This may require special needs, such as medical buildings, etc. Designers can choose roofing options based on the proposed project.